WORKHOOD

The Extracted worktable for AM Labs

WORKHOOD is a configurable fume hood designed for additive manufacturing labs, protecting operators from harmful dust and vapors. It integrates specific accessories for 3D printers, a HEPA filtration system, air quality sensors, and a camera with component recognition. The user interface provides access to ANY3DP.APP, and the hood automatically turns on thanks to presence detection.

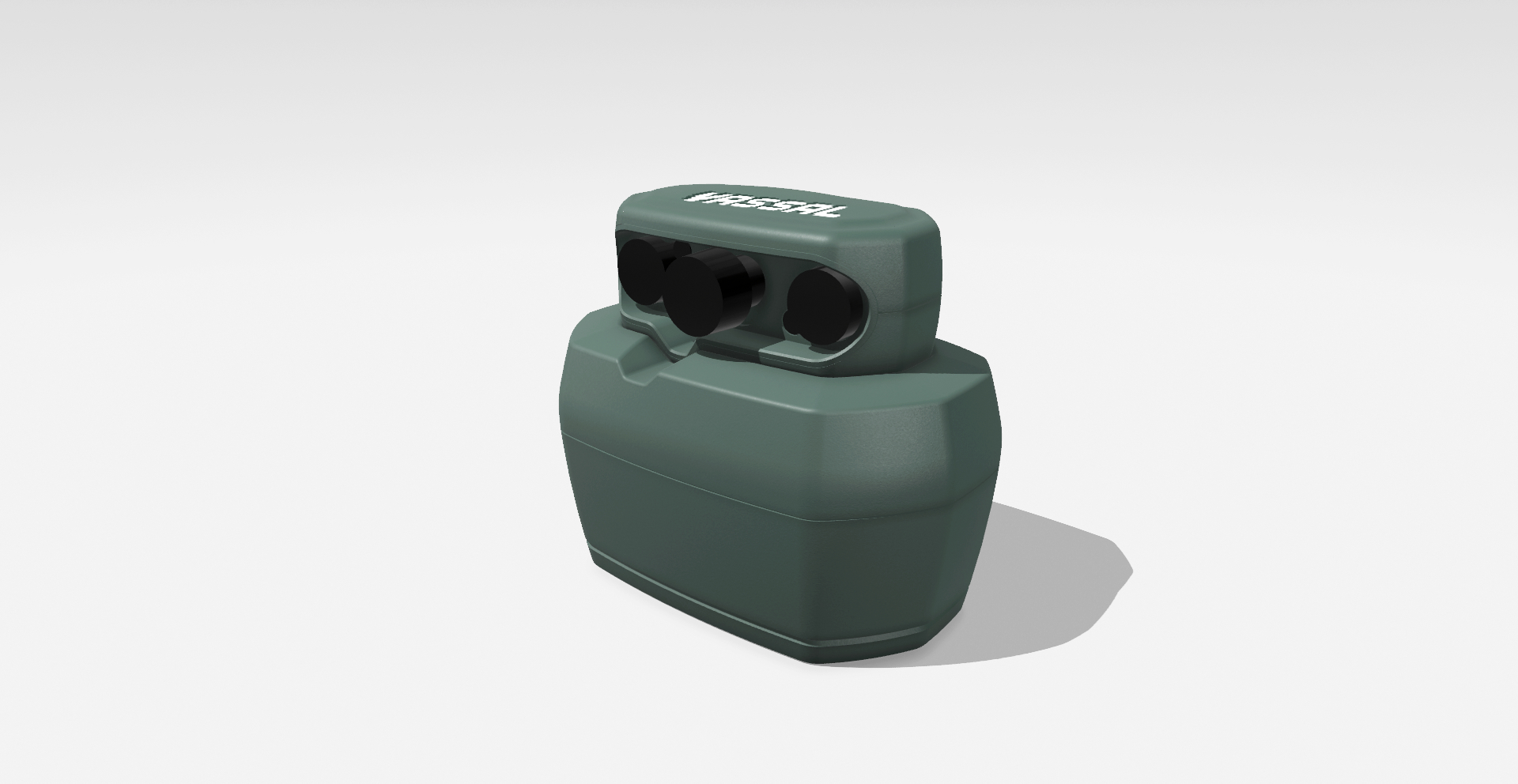

VASSAL

Sensors & Camera in-a-box

VASSAL is a smart device with a 3D-printed shell, designed for advanced environmental monitoring. Equipped with temperature, humidity sensors and a camera, it collects and transmits real-time data for precise control. Integrated with the ANY3DP suite, it enables instant visualization, storage, and predictive analysis, improving efficiency and safety in production processes.

REWORK

Mechanical Finishing for Additive Manufacturing

REWORK is a connected benchtop CNC milling machine, ideal for finishing parts produced with additive manufacturing. Compact and precise, it enables milling, drilling, surfacing, and engraving operations with an intuitive interface. Integrated with the ANY3DP suite, it provides real-time monitoring and historical data collection, optimizing the production workflow with automation and advanced control.

EASYDYE

A smart way for dyeing

EASYDYE is an intelligent system that optimizes the dyeing of 3D printed parts, ensuring uniform and repeatable color thanks to precise temperature and flow control. Integrated with the ANY3DP suite, it combines automation, efficiency, and customization. It reduces time and operational costs, turning the dyeing process into a competitive advantage.

3DMIND

The digital brain of the suite, private.

3DMIND is the digital heart of the ANY3DP suite: an industrial Linux computer, designed to guarantee maximum security, privacy, and data control. It allows you to install ANY3DP.APP in self-hosted on-premise mode, offering all the advanced features of the platform without relying on the cloud. Ideal for companies wishing to keep sensitive data within their own infrastructure, 3DMIND ensures high performance, automatic updates, and native integration with all ANY3DP smart devices. The ultimate solution for those who want autonomy, scalability, and total protection of production information.